Technological processes

SINTUR implements the entire technological process of producing refrigeration products, from raw materials to complete products with corrosion protection, controlling their quality at every stage. Our machine park allows us to perform all processing stages from straightening, cutting, bending, forming, welding to soldering. Most of the technological processes are automated and supervised by programmable controllers.

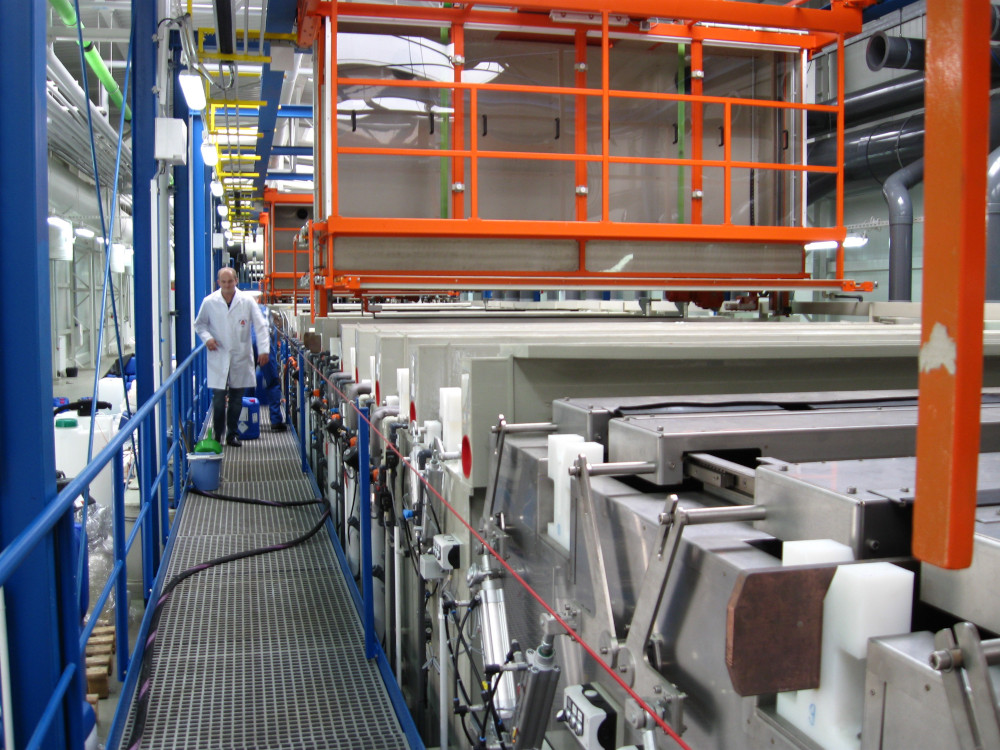

Our activities are aimed at automating all technological processes to ensure high repeatability and make the product quality independent of the employee's skill level. The company's innovative and pro-ecological aspirations have led to the launch of a very modern automatic electroplating line. High specialization allows us to improve the quality of products and quickly respond to the needs of the recipient.

Applied technological processes:

Steel, copper and aluminum pipe processing up to ∅ 11 :

- straightening

- chipless cutting

- 2D and 3D bending

- tube flaring

- fawning

- crimping

- mugging

Wire processing:

- straightening

- cutting

- chamfering

- bending

Welding:

- Spot - welding

- multispot - welding

- butt welding

In addition, we also implement

- Stamping sheets and strips on eccentric presses from 6.3 T to 63T

- Gas soldering

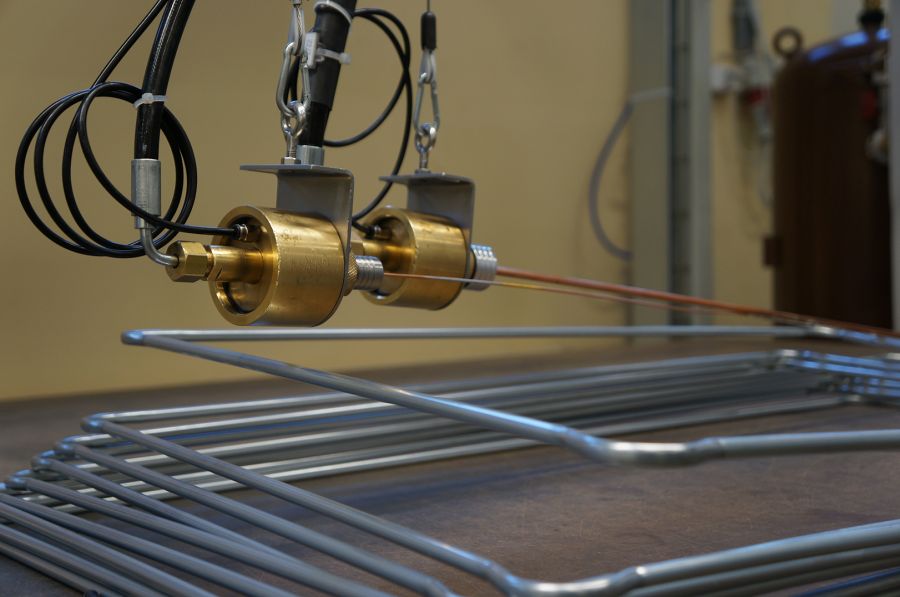

- Induction brazing

- Plastics processing on injection molding machines up to 130g