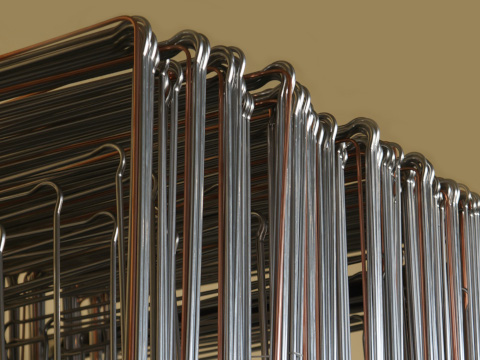

Chest freezer evaporators

used as a subassembly of the cooling system in integrated refrigerators and chest freezers.

Chest freezer evaporators

Chest freezer evaporator used as a subassembly of the cooling system in integrated coolers and chest freezers, intended for storage and display of broadly understood food products in gastronomy and commercial establishments.

Chest freezer evaporators are made in accordance with the documentation and requirements provided by customers, they can be supplied with heat exchangers and batteries as part of a completely assembled and tested evaporator system. We use technologies that ensure consistently good quality evaporators, such as resistance welding for connecting aluminum and copper pipes, induction soldering for soldering other pipe connections, bending in an automatic bender.

Our highly automated production processes allow us to supply a wide range of sizes of evaporators bent into rectangular or trapezoidal streamers.

- Max dimensions of the evaporator - 1000 x 2500 mm,

- The minimum dimensions of the evaporator - 280 x 450 mm.

Our evaporators are made of D- shaped tube and „gooseneck” corners, which allows them to better fit into the cooling chamber. To increase the efficiency of evaporators, it is also possible to make them with a D-shaped tube coating on straight sections and with no flattening in the places of bent corners. The evaporators are made of aluminum, copper or steel pipes, also in galvanized version. On each of the evaporators 100% is performed:

- pressure test at 30 bar pressure,

- patency test,

- helium leak test - leak detection is 2.5x10-6 mbar / s,

- capillary flow rate test (if equipped with an evaporator).

Individual design specifications are available upon request after contacting sales.

Tubular evaporators

Tubular evaporators, also called wrapped with a main purpose for ice cream conservators.

They are made in accordance with the documentation and requirements provided by customers, they can be supplied with heat exchangers and batteries as part of a completely assembled and tested evaporator system.

Our highly automated production processes allow us to supply a wide range of sizes in consistently good quality evaporators bent into rectangular serpentine.

- Max dimensions of the evaporator - 1000 x 2500 mm,

- The minimum dimensions of the evaporator - 280 x 450 mm.

Our evaporators are made of D-shaped tubes to better fit them into the cooling chamber. To increase the efficiency of evaporators, it is also possible to make them with a D-shaped tube coating on straight sections and with no flatness at the bent corners.

Tubular evaporators can be made of aluminum, copper or steel pipes, also in galvanized version.

On each of the evaporators 100% is performed:

- pressure test at 30 bar pressure,

- patency test,

- helium leak test - leak detection is 2.5x10-6 mbar / s,

- capillary flow rate test (if equipped with an evaporator).

Individual design specifications are available upon request after contacting with sales department.

Helium leak test service for pipes with cross-sections up to 10mm.

The leak test stand has the ability to perform 4 tests:

- Pressure test - performed with dry nitrogen for a pressure up to 30 bar.

- Patency test - the amount of pressure and the time it was obtained will allow you to assess the patency of the tubes, in particular the capillaries.

- Leak test - performed with helium at a pressure of 5-10 bar, leak detection is 2.5x10-6 mbar / s.

- Capillary flow rate test - performed up to 30 liters / min.

All tests take place in an automatic cycle, under the supervision of a program that records the course and results of tests, signaling the operator any deviation from the norm. Storing test history in the memory and full program control over the course of this operation guarantee full tightness and patency of the system as well as correctness of connections.